product Center

Low Temperature Debinding Furnace , 1100 ℃ Decreasing Furnace Electric Ceramic Furnace

- Introduction

Product Details:

Place of Origin:China

Brand Name:Facerom Furnace

Certification:CE

Model Number:FGL-TZL / FMJ-TZL

Payment & Shipping Terms:

Minimum Order Quantity:1 Set

Price:Negotiation

Packaging Details:Strong wooden box for global shipping

Delivery Time:7-21 Working days

Payment Terms:L/C, T/T, Western Union

Supply Ability:200 Sets per month

MAX. TEMPERATURE:1100℃CAPACITY:36 ~ 512L

TEMPERATURE CONTROL:50 Segments Programmable And PID Auto ControlAIR SYSTEM:Air Entering System Included

PREHEATING:Air Preheating System IncludedHEATING SIDE:5 Sides Heating

MAX. HEATING RATE:30°C /minTEMPERATURE ACCURACY:±1℃

TEMPERATURE UNIFORMITY:±5℃

HIGH LIGHT:high temperature box furnace, electric ceramic furnace

Low Temperature Debinding Furnace (1100℃)

Low Temperature Debinding Furnace, 1100℃ Decreasing Furnace, Debinding Furnace

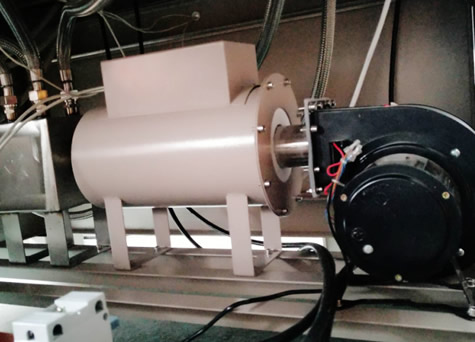

This furnace is mainly used in the process of casting, injection molding, 3D printing, dry pressing, advanced ceramics, metal, glass, plastic, and composite materials. It can also be used for magnetic materials, ceramic chips, ferrites. Debinding and pre-burning process of magnetic sheets and other electronic components. The unique thermal field control technology ensures the uniformity of the temperature field and required for the two process stages of debinding and sintering.

Molybdenum-containing resistance wire, the maximum temperature is 1100℃.

To ensure the ideal temperature field uniformity, heating in 5 sides.

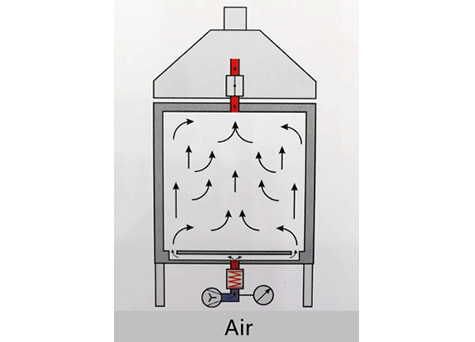

In order to speed up the discharge of exhaust gas and prevent the high concentration of hydrocarbons released from the rubber discharge with the danger of explosion. This electric furnace is designed with fresh air entering the system.

In order to prevent the unevenness of thermal field temperature fluctuation by fresh air, there is a design of the fresh air preheating system and the ceramic tube homogenization system, which can greatly improve the temperature uniformity.

The exhaust gas collected to collecting cover of the furnace top through the electric exhaust cover, and collect the cooled wax.

Standard Spares:

High-temperature gloves

Crucible clip

Operation Manual

Optional Spares:

Mullite multi-layer shelf.

Exhaust gas pyrolysis package to pyrolyze the irritating organic matter.

Place of Origin:China

Brand Name:Facerom Furnace

Certification:CE

Model Number:FGL-TZL / FMJ-TZL

Payment & Shipping Terms:

Minimum Order Quantity:1 Set

Price:Negotiation

Packaging Details:Strong wooden box for global shipping

Delivery Time:7-21 Working days

Payment Terms:L/C, T/T, Western Union

Supply Ability:200 Sets per month

MAX. TEMPERATURE:1100℃CAPACITY:36 ~ 512L

TEMPERATURE CONTROL:50 Segments Programmable And PID Auto ControlAIR SYSTEM:Air Entering System Included

PREHEATING:Air Preheating System IncludedHEATING SIDE:5 Sides Heating

MAX. HEATING RATE:30°C /minTEMPERATURE ACCURACY:±1℃

TEMPERATURE UNIFORMITY:±5℃

HIGH LIGHT:high temperature box furnace, electric ceramic furnace

Low Temperature Debinding Furnace (1100℃)

Low Temperature Debinding Furnace, 1100℃ Decreasing Furnace, Debinding Furnace

This furnace is mainly used in the process of casting, injection molding, 3D printing, dry pressing, advanced ceramics, metal, glass, plastic, and composite materials. It can also be used for magnetic materials, ceramic chips, ferrites. Debinding and pre-burning process of magnetic sheets and other electronic components. The unique thermal field control technology ensures the uniformity of the temperature field and required for the two process stages of debinding and sintering.

Molybdenum-containing resistance wire, the maximum temperature is 1100℃.

To ensure the ideal temperature field uniformity, heating in 5 sides.

In order to speed up the discharge of exhaust gas and prevent the high concentration of hydrocarbons released from the rubber discharge with the danger of explosion. This electric furnace is designed with fresh air entering the system.

In order to prevent the unevenness of thermal field temperature fluctuation by fresh air, there is a design of the fresh air preheating system and the ceramic tube homogenization system, which can greatly improve the temperature uniformity.

The exhaust gas collected to collecting cover of the furnace top through the electric exhaust cover, and collect the cooled wax.

Standard Spares:

High-temperature gloves

Crucible clip

Operation Manual

Optional Spares:

Mullite multi-layer shelf.

Exhaust gas pyrolysis package to pyrolyze the irritating organic matter.

Technical Parameter:

| Model | Heating zone (mm) | Temp. | Power | Votage |

| FGL-TZL-334 | 300*300*400 | 1100℃ | 12KW | 380V |

| FGL-TZL-555 | 500*500*500 | 1100℃ | 25KW | 380V |

| FGL-TZL-666 | 600*600*600 | 1100℃ | 36KW | 380V |

| FGL-TZL-888 | 800*800*800 | 1100℃ | 64KW | 380V |

Why Us?

Manufacturer with 10+ years' experience

Best quality

Customized design

Experienced workers

Big factory

Customers from more than 30 countries choose us

Satisfied customers offer proof of our commitment to excellent design, quality and cost efficiency.

Best service, Fast response

Free design for special furnace

Free technical support for the lifetime

Free sample test

Related products

-

Low Temperature Debinding Furnace , 1100 ℃ Decreasing Furnace Electric Ceramic Furnace

Low Temperature Debinding Furnace , 1100 ℃ Decreasing Furnace Electric Ceramic Furnace -

4 Sides Debinding Furnace Integrated Sintering For Casting / Injection Molding

4 Sides Debinding Furnace Integrated Sintering For Casting / Injection Molding -

Graphite Rod Vacuum Debinding Furnace , 10Pa Negative Pressure Switch Gas Furnace

Graphite Rod Vacuum Debinding Furnace , 10Pa Negative Pressure Switch Gas Furnace -

Electric Ceramic Oven Debinding Furnace , 1100 C High Temperature Box Furnace

Electric Ceramic Oven Debinding Furnace , 1100 C High Temperature Box Furnace -

36 - 512L Debinding Furnace , 1100 ℃ High Temperature Wax Burnout Furnace

36 - 512L Debinding Furnace , 1100 ℃ High Temperature Wax Burnout Furnace