product Center

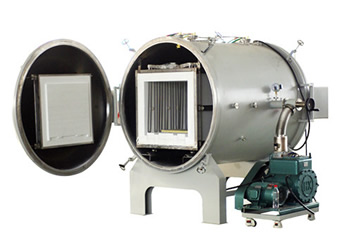

Durable High Temperature Vacuum Furnace 0.006 Pa Pressure For Oil Quenching

- Introduction

Product Details:

Place of Origin:China

Brand Name:Facerom Furnace

Certification:CE

Model Number:FGL-YCL

Payment & Shipping Terms:

Minimum Order Quantity:1 Set

Price:Negotiation

Packaging Details:Strong wooden box for global shipping

Delivery Time:30-50 Working days

Payment Terms:L/C, T/T, Western Union

Supply Ability:200 Sets per month

MAX. VACUUM:0.006PaMAX. TEMPERATURE:1320℃

CAPACITY:500kgs Max.FURNACE CHPHITEAMBER:Graphite

HEATING ELEMENT:GraphiteSTRUCTURE:Double Room

CONTROL:PLCMAX. HEATING RATE:20°C /min

TEMPERATURE ACCURACY:±1℃TEMPERATURE UNIFORMITY:±5℃

HIGH LIGHT:vacuum annealing furnace, electric heat treatment furnace

Vacuum Oil Quenching Furnace

The vacuum oil quenching furnace is mainly used in bright quenching and annealing of alloy steel, tool steel, die steel, high speed steel, bearing steel, spring steel, stainless steel. Also used in vacuum sintering of ceramic and hard alloy, metal material brazing, etc. The furnace is mainly composed of graphite chamber, graphite felt induction, PLC control system.

Adopt the graphite tube as the heating element, with long lifetime and easy maintenance.

The compound flash-board has excellent heat insulation and trapping effect.

The structure is a double room, the back room is for heating and the front room is for oil and gas cooling. The upside is the gas quenching room and the downside is the oil quenching room, including lifting device, charging device, oil mixing device, and oil heating device.

Lifting device: The lifting skip car is driving by screw and nut, and driving by a three-speed gear motor. There is three speed on lifting skip car, low speed for sending material, low-speed start, high-speed oil quenching, and low-speed location.

Oil mixing system: The mixer is driving by the reducer, the deflector could promote the circular flowing of vacuum quenching and promote the oil cooling capacity. The mixer is a standard part of low noise and high efficiency.

The workpiece transfer is smooth and flexible, safe and reliable.

The gas cooling cover adopts a staggered teeth flange structure to ensure the sealing in positive and negative pressure.

Place of Origin:China

Brand Name:Facerom Furnace

Certification:CE

Model Number:FGL-YCL

Payment & Shipping Terms:

Minimum Order Quantity:1 Set

Price:Negotiation

Packaging Details:Strong wooden box for global shipping

Delivery Time:30-50 Working days

Payment Terms:L/C, T/T, Western Union

Supply Ability:200 Sets per month

MAX. VACUUM:0.006PaMAX. TEMPERATURE:1320℃

CAPACITY:500kgs Max.FURNACE CHPHITEAMBER:Graphite

HEATING ELEMENT:GraphiteSTRUCTURE:Double Room

CONTROL:PLCMAX. HEATING RATE:20°C /min

TEMPERATURE ACCURACY:±1℃TEMPERATURE UNIFORMITY:±5℃

HIGH LIGHT:vacuum annealing furnace, electric heat treatment furnace

Vacuum Oil Quenching Furnace

The vacuum oil quenching furnace is mainly used in bright quenching and annealing of alloy steel, tool steel, die steel, high speed steel, bearing steel, spring steel, stainless steel. Also used in vacuum sintering of ceramic and hard alloy, metal material brazing, etc. The furnace is mainly composed of graphite chamber, graphite felt induction, PLC control system.

Adopt the graphite tube as the heating element, with long lifetime and easy maintenance.

The compound flash-board has excellent heat insulation and trapping effect.

The structure is a double room, the back room is for heating and the front room is for oil and gas cooling. The upside is the gas quenching room and the downside is the oil quenching room, including lifting device, charging device, oil mixing device, and oil heating device.

Lifting device: The lifting skip car is driving by screw and nut, and driving by a three-speed gear motor. There is three speed on lifting skip car, low speed for sending material, low-speed start, high-speed oil quenching, and low-speed location.

Oil mixing system: The mixer is driving by the reducer, the deflector could promote the circular flowing of vacuum quenching and promote the oil cooling capacity. The mixer is a standard part of low noise and high efficiency.

The workpiece transfer is smooth and flexible, safe and reliable.

The gas cooling cover adopts a staggered teeth flange structure to ensure the sealing in positive and negative pressure.

Technical parameter:

| Model | Working size | Max.Temp | Capacity | Temperature uniformity | Power | Ultimate vacuum |

| FGL-YCL-334 | 300*300*450 | 1320℃ | 100kgs | ±5℃ | 50KW | 6x10-3Pa |

| FGL-YCL-446 | 400*400*600 | 1320℃ | 200kgs | ±5℃ | 80KW | 6x10-3Pa |

| FGL-YCL-557 | 500*500*700 | 1320℃ | 300kgs | ±5℃ | 120KW | 6x10-3Pa |

| FGL-YCL-669 | 600*600*900 | 1320℃ | 500kgs | ±5℃ | 150KW | 6x10-3Pa |

Why Us?

Manufacturer with 10+ years' experience

Best quality

Customized design

Experienced workers

Big factory

Customers from more than 30 countries choose us

Satisfied customers offer proof of our commitment to excellent design, quality and cost efficiency.

Best service, Fast response

Free design for special furnace

Free technical support for the lifetime

Free sample test

Related products

-

Non Pressure Horizontal Vacuum Furnace , Electric Heat Treatment Furnace For Si3N4 Powder

Non Pressure Horizontal Vacuum Furnace , Electric Heat Treatment Furnace For Si3N4 Powder -

High Performance Graphite Vacuum Furnace , Periodic Vertical Vacuum Furnace up to 2200℃

High Performance Graphite Vacuum Furnace , Periodic Vertical Vacuum Furnace up to 2200℃ -

Graphite Ultra High Temperature Vacuum Furnace Horizontal Type 12 - 324L Capacity

Graphite Ultra High Temperature Vacuum Furnace Horizontal Type 12 - 324L Capacity -

Tungsten Coil High Temperature Vacuum Furnace 50 Segments Programmable

Tungsten Coil High Temperature Vacuum Furnace 50 Segments Programmable -

Induction High Temperature Vacuum Melting Furnace Medium Frequency Alloy Feeder

Induction High Temperature Vacuum Melting Furnace Medium Frequency Alloy Feeder -

PLC 20T Vacuum Hot Press Furnace , Up To 2000 ℃ Vacuum Carburizing Furnace

PLC 20T Vacuum Hot Press Furnace , Up To 2000 ℃ Vacuum Carburizing Furnace -

1320 ℃ Gas Quenching Vacuum Furnace , Heavy Weight Industrial Vacuum Furnace

1320 ℃ Gas Quenching Vacuum Furnace , Heavy Weight Industrial Vacuum Furnace -

Durable High Temperature Vacuum Furnace 0.006 Pa Pressure For Oil Quenching

Durable High Temperature Vacuum Furnace 0.006 Pa Pressure For Oil Quenching -

1 - 324 L Vacuum Sintering Furnace , Alumina Ceramic Fiber Electric Heat Treat Oven

1 - 324 L Vacuum Sintering Furnace , Alumina Ceramic Fiber Electric Heat Treat Oven -

High Temperature Vacuum Annealing Furnace , 1 - 324 L Industrial Vacuum Furnace

High Temperature Vacuum Annealing Furnace , 1 - 324 L Industrial Vacuum Furnace -

Melting 0.007Pa High Temperature Vacuum Furnace Up To 1700 ℃ High Performance

Melting 0.007Pa High Temperature Vacuum Furnace Up To 1700 ℃ High Performance -

High Temp Vacuum Hot Pressing Furnace With PLC Auto Control Stable Performance

High Temp Vacuum Hot Pressing Furnace With PLC Auto Control Stable Performance -

Medium Frequency Vacuum Induction Melting Furnace High Temperature Alloy

Medium Frequency Vacuum Induction Melting Furnace High Temperature Alloy -

Operation Manual High Temperature Vacuum Furnace Heat Treatment Furnace 1 - 324L Capacity

Operation Manual High Temperature Vacuum Furnace Heat Treatment Furnace 1 - 324L Capacity -

Easy Operation High Temperature Vacuum Furnace With Vacuum Pump 1700℃ Max Temperature

Easy Operation High Temperature Vacuum Furnace With Vacuum Pump 1700℃ Max Temperature -

4000HZ 1700℃ Induction High Temperature Vacuum Furnace

4000HZ 1700℃ Induction High Temperature Vacuum Furnace -

Alloy Feeder 0.006Pa 1700℃ Vacuum Induction Furnace

Alloy Feeder 0.006Pa 1700℃ Vacuum Induction Furnace -

PLC 10Pa 324L 1200 Degree Vacuum Debinding Furnace

PLC 10Pa 324L 1200 Degree Vacuum Debinding Furnace -

250kg 1700℃ Medium Frequency Induction Furnace For Melting

250kg 1700℃ Medium Frequency Induction Furnace For Melting -

1200 Degree Vacuum Heat Treatment Furnace With Gas Protection

1200 Degree Vacuum Heat Treatment Furnace With Gas Protection -

High Temperature 100kg Vacuum Induction Furnace 4000HZ

High Temperature 100kg Vacuum Induction Furnace 4000HZ -

2000 Degree Industrial PLC 20T Vacuum Press Furnace

2000 Degree Industrial PLC 20T Vacuum Press Furnace -

10kg Induction High Temperature Vacuum Furnace 1500HZ

10kg Induction High Temperature Vacuum Furnace 1500HZ -

IGBT 1700 Degree VIM High Temperature Vacuum Furnace For Casting

IGBT 1700 Degree VIM High Temperature Vacuum Furnace For Casting -

1700 Degree High Temperature Vacuum Furnace DPF Sintering Furnace

1700 Degree High Temperature Vacuum Furnace DPF Sintering Furnace -

Graphite High Temperature Vacuum Furnace 500kgs Gas Quenching Furnace

Graphite High Temperature Vacuum Furnace 500kgs Gas Quenching Furnace -

Fast Cooling High Temperature Vacuum Furnace Vacuum Quench Furnace

Fast Cooling High Temperature Vacuum Furnace Vacuum Quench Furnace -

Vacuum Induction Skull Melting Furnaces for melting & casting of refractory

Vacuum Induction Skull Melting Furnaces for melting & casting of refractory -

1200℃ / 1700℃ 10 Pa High Temperature Vacuum Furnace With Pneumatic Vacuum Valve

1200℃ / 1700℃ 10 Pa High Temperature Vacuum Furnace With Pneumatic Vacuum Valve -

Programmable High Temperature Vacuum Furnace , Automatic Vacuum Hardening Furnace

Programmable High Temperature Vacuum Furnace , Automatic Vacuum Hardening Furnace -

Pneumatic High Temperature Vacuum Furnace Easy To Operate With Air Inlet

Pneumatic High Temperature Vacuum Furnace Easy To Operate With Air Inlet