- Introduction

Place of Origin:China

Brand Name:Facerom Furnace

Certification:CE

Model Number:FGL-18HM / FMJ-18HM

Payment & Shipping Terms:

Minimum Order Quantity:1 Set

Price:Negotiation

Packaging Details:Strong wooden box for global shipping

Delivery Time:7-21 Working days

Payment Terms:L/C, T/T, Western Union

Supply Ability:200 Sets per month

MAX WORKING TEMPERATURE:1800℃VOLUME:1 ~ 8L

HEATING ELEMENT:Super MoSi2 Heating ElementFURNACE CHAMBER:Ceramic Fiber Chamber Imported From Japan, Ultra-high Temperature Coating Inside

TEMPERATURE CONTROL:50 Segments Programmable And PID Auto ControlALARM:With Over Temperature Alarm Function

COOLING:Cooling Fan Can Reduce The Temperature Of The CasingVOTAGE:AC 110V Or AC 220V Or AC 380V 50/60 Hz

MAX. HEATING RATE:20°C /minTEMPERATURE ACCURACY:±1℃

TEMPERATURE UNIFORMITY:±5℃APPLICATION:Industrial Annealing Under 1800°C

HIGH LIGHT:vacuum muffle furnace, industrial metal melting furnace

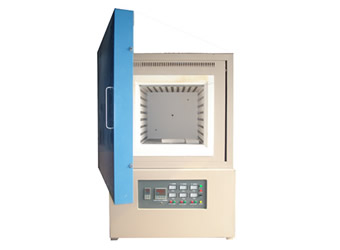

1800℃ High Temperature Industrial Annealing Muffle Furnace, 1800C Industrial Annealing Box Furnace

Facerom's 1800℃ High Temperature Industrial Annealing Muffle Furnace, 1800C Industrial Annealing Box Furnace mainly used for production enterprises for the industrial annealing under 1800℃.

Facerom muffle furnace using polycrystalline mullite fiber lining, and the total thickness is 120-250mm, to ensure the very good thermal effect. Double layer of furnace shell with fan cooling, the surface temperature is less than 60℃. Strength structured furnace roof, to ensure long life to avoid any collapse from continuous working.

This furnace is mainly used for universities, research institutes and production enterprises for the sintering, melting, analysis of metal, non-metal and other compound materials.

Max working temperature 1800℃

Volume: as per your order

Super MoSi2 heating element.

Ceramic fiber chamber imported from Japan, ultra-high temperature coating inside.

50 segments programmable and PID auto control

With over temperature alarm function

Double layer of furnace shell with fan cooling, the Surface temperature is less than 60℃

Ultra High Temp Coating Small Annealing Oven , 1 - 8L Programmable Muffle Furnace 0

Standard Spares:

Fire brick

High temperature gloves

Crucible clip

Operation Manual

Optional Spares:

7-inch touch screen

Gas vent

Observation hole

Software

Furnace furniture as per your requirement.

Alumina crucible as per your requirement

Special design as per your requirement

1800℃ High Temperature Industrial Annealing Muffle Furnace Technical Parameter:

| Model |

Max Temperature (℃) |

Inner size (W *H * D) mm |

Volume (L) |

Power (KW) |

Phase | Thermocouple |

| FGL-18HM-1 | 1800 | 100*100*100 | 1 | 2 | 1 | B type |

| FGL-18HM-2 | 1800 | 120*120*130 | 2 | 4 | 1 | B type |

| FGL-18HM-3 | 1800 | 150*150*150 | 3 | 6 | 1 | B type |

| FGL-18HM-5 | 1800 | 150*150*200 | 5 | 7 | 1 | B type |

| FGL-18HM-8 | 1800 | 200*200*200 | 8 | 8 | 1 | B type |

Other chamber sizes can be customized.

Why Facerom's 1800℃ High Temperature Industrial Annealing Box Furnace?

Manufacturer with 10+ years' experience

Best quality

Customized design

Experienced workers

Big factory

Customers from more than 30 countries choose us

Satisfied customers offer proof of our commitment to excellent design, quality and cost efficiency.

Best service, Fast response

Free design for special furnace

Free technical support for the lifetime

Free sample test

If you're inerested in our 1800℃ High Temperature Industrial Annealing Muffle Furnace, 1800C Industrial Annealing Box Furnace, contact us now to get a quote!

-

Industrial Large Muffle Furnace , Custom Temperature Electric Annealing Furnace

Industrial Large Muffle Furnace , Custom Temperature Electric Annealing Furnace -

Ceramic Fiber Chamber Electric Muffle Furnace , Manual High Temperature Muffle Furnace

Ceramic Fiber Chamber Electric Muffle Furnace , Manual High Temperature Muffle Furnace -

Heat Treatment Industrial Muffle Furnace 1400C Polycrystalline Mullite Fiber Lining

Heat Treatment Industrial Muffle Furnace 1400C Polycrystalline Mullite Fiber Lining -

Continuous Industrial Muffle Furnace Strength Structured Roof Easy To Use

Continuous Industrial Muffle Furnace Strength Structured Roof Easy To Use -

MoSi2 Heating Element Heat Treatment Muffle Furnace 1800 C For Production Enterprises

MoSi2 Heating Element Heat Treatment Muffle Furnace 1800 C For Production Enterprises -

Ceramic Kilns Industrial Muffle Furnace Over Temperature Alarm CE Approval

Ceramic Kilns Industrial Muffle Furnace Over Temperature Alarm CE Approval -

7 Inch Touch Screen Vacuum Muffle Furnace 1200 C For Industry Movable

7 Inch Touch Screen Vacuum Muffle Furnace 1200 C For Industry Movable -

Automatic Industrial Muffle Furnace 1400 ℃ High Temperature SiC Heating Element

Automatic Industrial Muffle Furnace 1400 ℃ High Temperature SiC Heating Element -

Collapse Proof Vacuum Sintering Furnace B Type MoSi2 Heating Element Custom Volume

Collapse Proof Vacuum Sintering Furnace B Type MoSi2 Heating Element Custom Volume -

Blue 1800 ℃ Industrial Muffle Furnace 1 - 8L Volume 50 Segments Programmable

Blue 1800 ℃ Industrial Muffle Furnace 1 - 8L Volume 50 Segments Programmable -

Manual Digital Muffle Furnace , Fire Brick Industrial Metal Melting Furnace

Manual Digital Muffle Furnace , Fire Brick Industrial Metal Melting Furnace -

Programmable Industrial Muffle Furnace 1400 C Box Shape Blue Color Double Layer

Programmable Industrial Muffle Furnace 1400 C Box Shape Blue Color Double Layer -

High Temp Industrial Melting Furnace , Vacuum Muffle Furnace With Cooling Fan

High Temp Industrial Melting Furnace , Vacuum Muffle Furnace With Cooling Fan -

High Temperature Industrial Muffle Furnace Melting Type 20 °C / Min Heating Rate

High Temperature Industrial Muffle Furnace Melting Type 20 °C / Min Heating Rate -

Annealing Chamber Industrial Muffle Furnace Programmable Strength Structured

Annealing Chamber Industrial Muffle Furnace Programmable Strength Structured -

Crucible Clip Small Muffle Furnace Industrial With SiC Heating Element

Crucible Clip Small Muffle Furnace Industrial With SiC Heating Element -

1700 ℃ High Temperature Industrial Muffle Furnace 50 / 60 Hz Frequency CE Listed

1700 ℃ High Temperature Industrial Muffle Furnace 50 / 60 Hz Frequency CE Listed -

Ultra High Temp Coating Small Annealing Oven , 1 - 8L Programmable Muffle Furnace

Ultra High Temp Coating Small Annealing Oven , 1 - 8L Programmable Muffle Furnace -

PID Auto Control Industrial Muffle Furnace 1200 C 50 Segments Ceramic Fiber Chamber

PID Auto Control Industrial Muffle Furnace 1200 C 50 Segments Ceramic Fiber Chamber -

SiC Heating Element Industrial Muffle Furnace 1400 C Over Temperature Alarm

SiC Heating Element Industrial Muffle Furnace 1400 C Over Temperature Alarm -

Fast Heating High Temperature Muffle Furnace 120 - 250mm Thickness Continuous Working

Fast Heating High Temperature Muffle Furnace 120 - 250mm Thickness Continuous Working -

Durable Industrial Tempering Oven , High Temperature Benchtop Muffle Furnace

Durable Industrial Tempering Oven , High Temperature Benchtop Muffle Furnace -

1200 ℃ Industrial Muffle Furnace For Production Enterprises Custom Volume

1200 ℃ Industrial Muffle Furnace For Production Enterprises Custom Volume -

Programmable Electric Muffle Furnace , 1400 ℃ Industrial Chamber Furnace

Programmable Electric Muffle Furnace , 1400 ℃ Industrial Chamber Furnace -

Metal Refining Industrial Muffle Furnace 20 °C / Min Heating Rate Double Layer

Metal Refining Industrial Muffle Furnace 20 °C / Min Heating Rate Double Layer -

1800 ℃ High Temp Industrial Muffle Furnace Metal Refining With Cooling Fan

1800 ℃ High Temp Industrial Muffle Furnace Metal Refining With Cooling Fan -

Aluminum / Metal Melting Crucible Furnace , 1200 ℃ Industrial Sintering Furnace

Aluminum / Metal Melting Crucible Furnace , 1200 ℃ Industrial Sintering Furnace